[NCBrain AICAM]

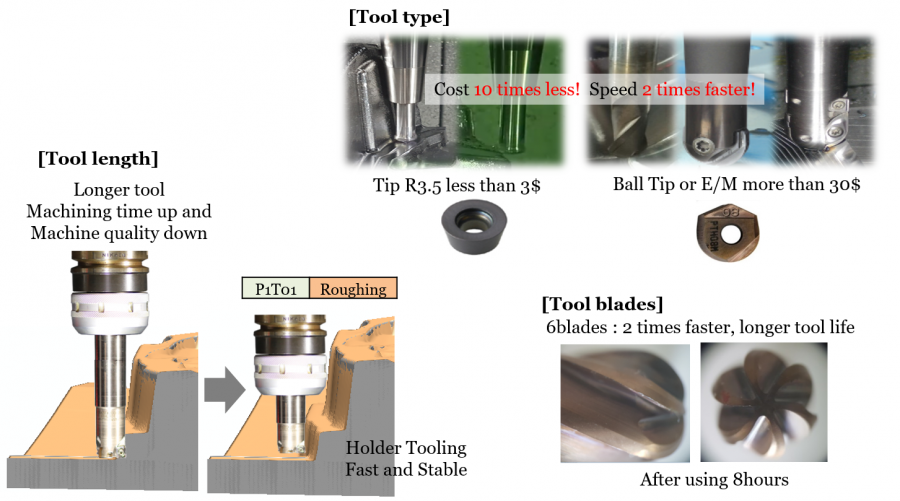

01. Why should use AICAM exclusive tools?

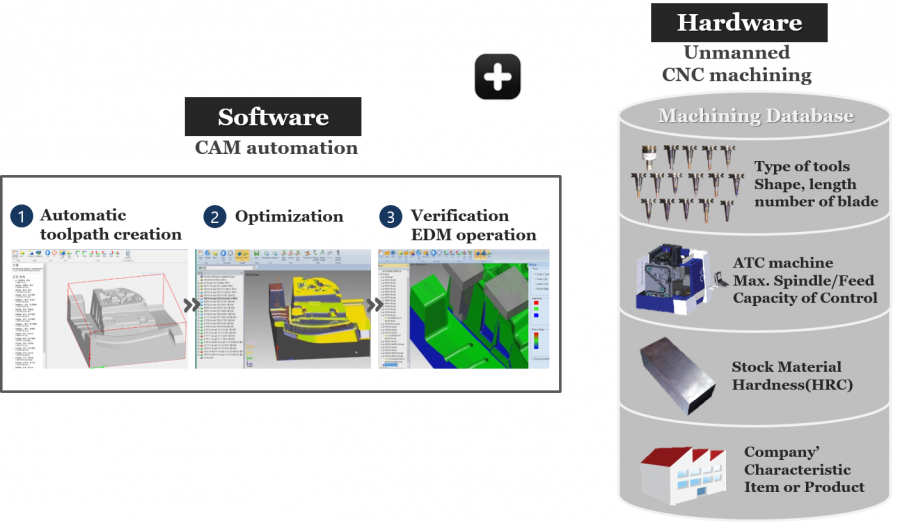

- It

is because of CAM automation and unmanned CNC machining.

- To

do so, the best combination S/W + H/W is necessary.

-

Besides, it is absolutely necessary to use the fifteen(15) exclusive holders

and tools of AICAM.

[NCBrain AICAM]

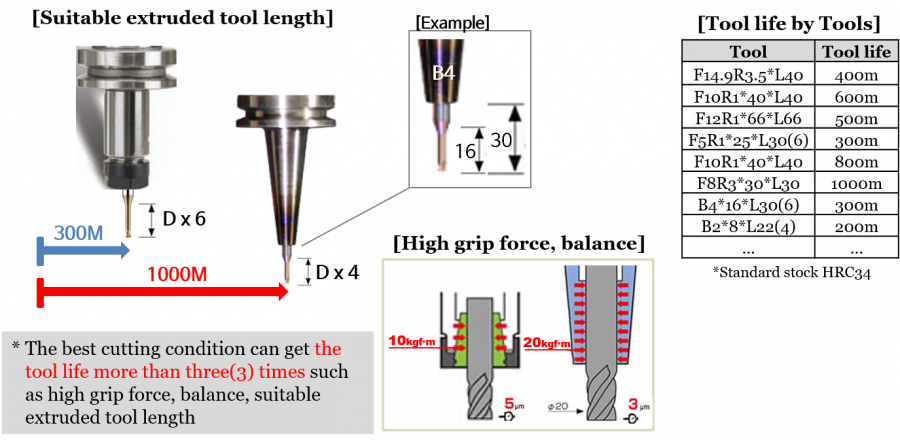

02. Is it possible to use End Mills made by other makers?

-

Yes, you can use the other’s end mills if grinded to fit the standard value.

- 6

blades and 0.5 corner radius tools can use and make as needed.

[NCBrain AICAM]

03. Is it possible to use existing chuck and add special tools?

-

First, it is absolutely necessary to use the fifteen(15) exclusive holders of

AICAM because the

machining parts is controlled by

the size of the shrink fit holder.

-

Yes, they can be used between process of

the essential fifteen(15) processing.

-

Additional processing requires a little manual handling.

[NCBrain AICAM]

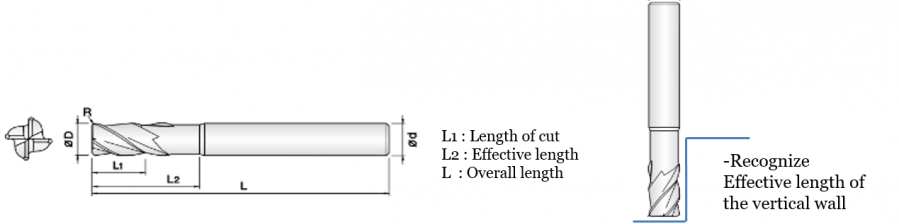

04. Curious about the Tool life, quality, price for AICAM shrink fit holders?

- Our

products are 1/2 or

2/3 times cheaper than

products of MST or HAIMER

companies.

- It

has high rigidity by 5 degree slope angle and 2.5~4 thickness

than general tool makers(3”).

- It

maintains longer life and more accuracy by the best cutting condition suitable

for rigidity of shrink fit holder.

- It

has higher accuracy and rigidity by all-in-one than 2piece chuck types.

- The

guarantee of quality supplied

[NCBrain AICAM]

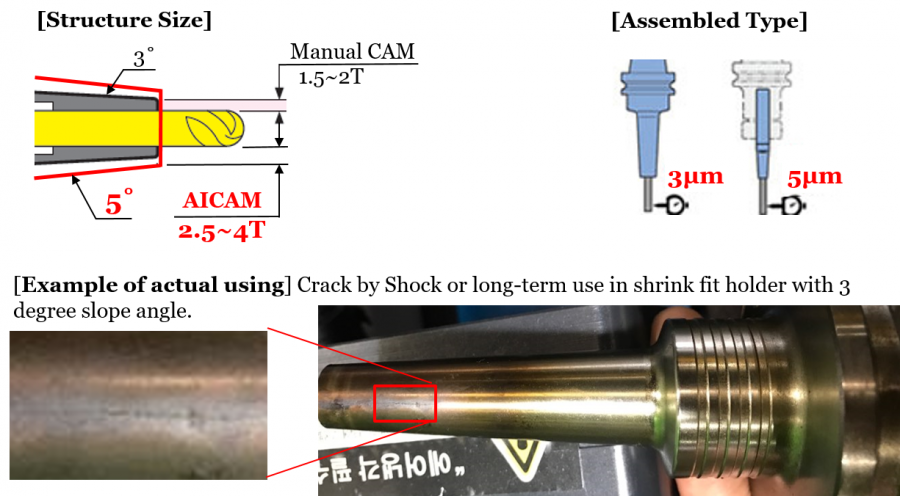

05. Curious about the Tool life, quality, price for AICAM exclusive end mills?

- AICAM E/M quality is equivalent

to ‘good’ Among the best, good, fair, and poor.

- End

mill prices is similar to existing standards.

- It

maintains long life and accuracy by 4-5 times of tool Dia extruded.

-

Grip force is 2 times of collet chuck.

-

Broken tools within specified tool life in the table below will be replaced

free of charge.

- 4M

of HRC30 can guarantee 2 times longer tool life in the table below.

[NCBrain AICAM]

06. How much affects the spending tools or machine life?

- It

reduces the average tool cost more than 30% by machining to Tip of R-cutter for

rough-residual, semi-finishing and 6 blades tool for finishing.

-

When using holder tooling, machine life is increased due to no overload in

rough machining of longer tool.

[NCBrain AICAM]

07. How much guarantees the cutting quality?

- It

differs depending on machine circumstance, but it can guarantee up to 2~1 Rz (μm) scallop height.

Mirror-like finishing is impossible

Mirror-like finishing is impossible

[NCBrain AICAM]

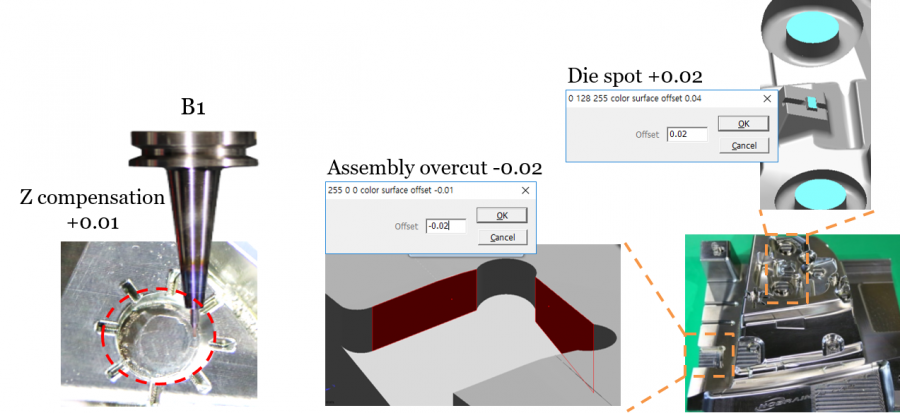

08. How much is accuracy machining?

-

It has high accuracy machining by

①

All-in-on shrink fit holder and

suitable tool setting length

②

Automatic Z compensation of Thermal

error

③

Error compensation such as movement

of tool, etc.

[NCBrain AICAM]

09. How’s the machining time?

[NCBrain AICAM]

10. Is it possible to machining heat treated materials for die-casting, press mold or aluminum materials?

-

Yes, it is possible to machining material such as HRC 55, SKD61, SKD11.

-

Cutting condition process of aluminum materials are established.