[NCBrain AICAM]

11. What’s the unmanned operating rate?

- Currently, tool preparation, setting are needed.

- The operating rate is lowered due to human errors

with manual CAM.

- In case of AICAM, the above work is not necessary by

using the fifteen(15) ATC and CAM automation.

- Complete unmanned through ATC management by dividing

NC data according to tool life.

[NCBrain AICAM]

12. How much is a defect rate?

-

Over/less cutting and collision have decreased sharply by verification.

- The

missing or interference of EDM is verified.

-

But

the

interface

error

of CAD data must be confirmed by the person.

[NCBrain AICAM]

13. What is different between manual CAM and AICAM?

-

Manual CAM

requires CNC engineers to machining.

- AICAM brings more benefit by

complete unmanned automation.

[NCBrain AICAM]

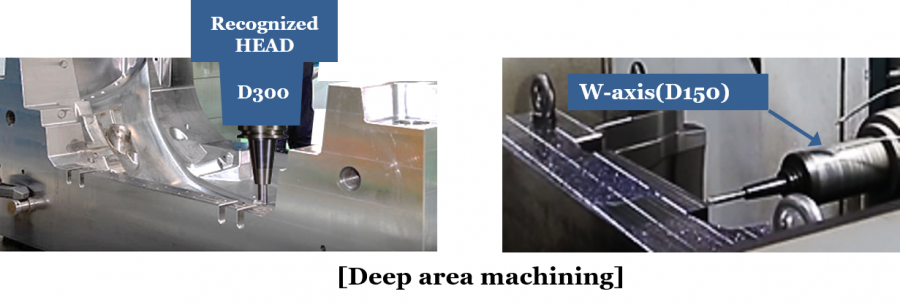

14. Is it possible to machining deep or large workpiece?

-

It can be machined if input NC Head or W-axis

size.

-

It can be machined if register customer’s

special long tool.

-

Large sized mold such as bumper is not recommended due to

excessive calculation time and NC data volume.

- The door trim is calculated stably.

[NCBrain AICAM]

15. Can residual off or finish off be excluded after Semi-finish or Finish machining in relief & EDM area, etc?

-

Yes,

you can specify the area to be excepted by color on modeling.

-

You

can set to only four(4)

processes of semi-finishing with D15r3.5 and D5r1,

whole finishing with D8R3, residual with Ball4

- It

is also possible by toolpath editing.